Microchannels thermal – hydraulic performance

Micro and minichannel heat sinks are the most effective heat dissipation devices from high heat flux generating components. The minichannel heat exchangers are getting more and more attention, due to their compact size and high-pressure durability in industrial applications. Moreover, nanofluids present high remarkably higher thermal conductivities even for very low concentrations. Nanofluids have been used in a variety of thermal applications ranging from energy storage systems to cancer therapy through hyperthermia that provoke tumor’s death by increasing locally the temperature.

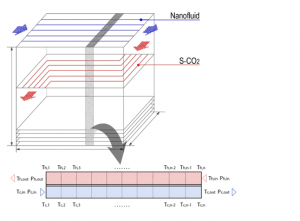

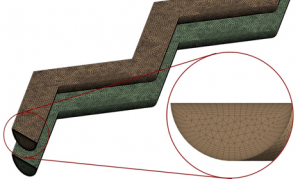

The Flow Analysis and Simulation Team of UNIWA investigates numerically the thermal-hydraulic performance of minichannels for waste heat recovery or other thermal applications, employing 1D and 3D in-house models. The main goal of this study is to examine how the nanoparticles affect the thermal-hydraulic performance of a minichannel heat exchanger. The use of nanofluids seems to enhance the heat transfer between the two working fluids, leading to slightly reduced heat exchanger length. On the other hand, the use of nanoparticles in the base fluid increase the pressure drop in the minichannels and in turn the pumping power.

Figure 1. 1D segmental analysis of heat exchanger, simulating the heat transfer between two minichannels.

Figure 2. Mesh of printed-circuit heat exchanger minichannels for CFD analysis.

Cooling processes

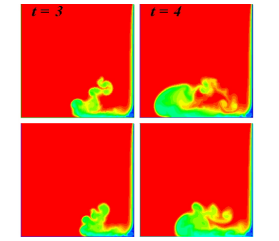

Direct numerical simulations were performed for the strongly transient and turbulent natural co nvection cooling of an initially isothermal quiescent liquid metal placed in a vertical cylinder in the presence of a vertical and constant magnetic field. The electrically conductive low-Prandtl number fluid is put to motion when the cylindrical wall is suddenly cooled to a uniform lower temperature. For this particular cooling process, the flow is characterized by the continuous transition among three almost discrete stages: a) development of momentum and thermal boundary layers along the vertical cold wall, b) intrusion of the cooled fluid into the main body, and c) flow and thermal stratification. The selected Rayleigh numbers in the present study are quite high such that, in the above three stages, turbulent convection is established. The numerical results show that imposing the magnetic field no observable effect is encountered at the initial stage of the vertical boundary layer development. Conduction heat transfer is favored during the intrusion stage and the cooling of the fluid is slower independently of the Rayleigh number. An interesting effect of the magnetic field is the deceleration or acceleration of the cooling process for low or high Rayleigh numbers, respectively.

nvection cooling of an initially isothermal quiescent liquid metal placed in a vertical cylinder in the presence of a vertical and constant magnetic field. The electrically conductive low-Prandtl number fluid is put to motion when the cylindrical wall is suddenly cooled to a uniform lower temperature. For this particular cooling process, the flow is characterized by the continuous transition among three almost discrete stages: a) development of momentum and thermal boundary layers along the vertical cold wall, b) intrusion of the cooled fluid into the main body, and c) flow and thermal stratification. The selected Rayleigh numbers in the present study are quite high such that, in the above three stages, turbulent convection is established. The numerical results show that imposing the magnetic field no observable effect is encountered at the initial stage of the vertical boundary layer development. Conduction heat transfer is favored during the intrusion stage and the cooling of the fluid is slower independently of the Rayleigh number. An interesting effect of the magnetic field is the deceleration or acceleration of the cooling process for low or high Rayleigh numbers, respectively.